Dive Into Our Detailed

Coffee Roasting Process

Our 5-Step Process

Creates the Perfect Cup

LaRue Coffee Roasterie is dedicated to creating small-batch coffee roasting processes that leave all coffee connoisseurs satisfied. We have invested countless hours refining our techniques, resulting in delicious, high-quality, gourmet coffee.

Our wide variety of flavor profiles cater to a diverse range of tastes and preferences - sure to please all your customers, employees, and guests. Our commitment to excellence shines through in every sip of our expertly crafted brews.

Green Coffee Selection

and Reception

Upon arrival in our facility, each batch of green coffee is meticulously sampled. The sample undergoes a moisture content test, is roasted on a sample roaster, and then cupped by our team to assess quality.

If it meets our standards, it is approved and assigned a unique lot number for precise traceability - from receipt through processing back to our supplier if necessary. Approved coffees are then stored in designated areas.

Storage & Cleaning

Each bag of green coffee is emptied in a designated area, where beans are conveyed through a cleaning system.

This system is crucial for removing dust, debris, and foreign objects, with a magnet ensuring metallic items are captured. The cleaned beans are then stored in one of six silos.

Roasting

The coffee is weighed and conveyed to a pre-hopper above our advanced roasting equipment. Here, the operator chooses a predefined roasting profile that dictates the roasting dynamics.

Our roasters employ dual heat transfer methods - convection and contact - to ensure uniform roasting with the process duration adjustable between 4 and 25 minutes to achieve the desired roast.

After reaching the target color and temperature, the beans are transferred to a cooling chamber where they are rapidly cooled for three minutes.

Post-Roast

Handling

Once cooled, the freshly roasted coffee is moved to a selected storage silo, ready for the next stage of production.

In our commitment to authenticity and quality, the flavoring process is crafted to enhance, not mask, the natural profile of our coffees.

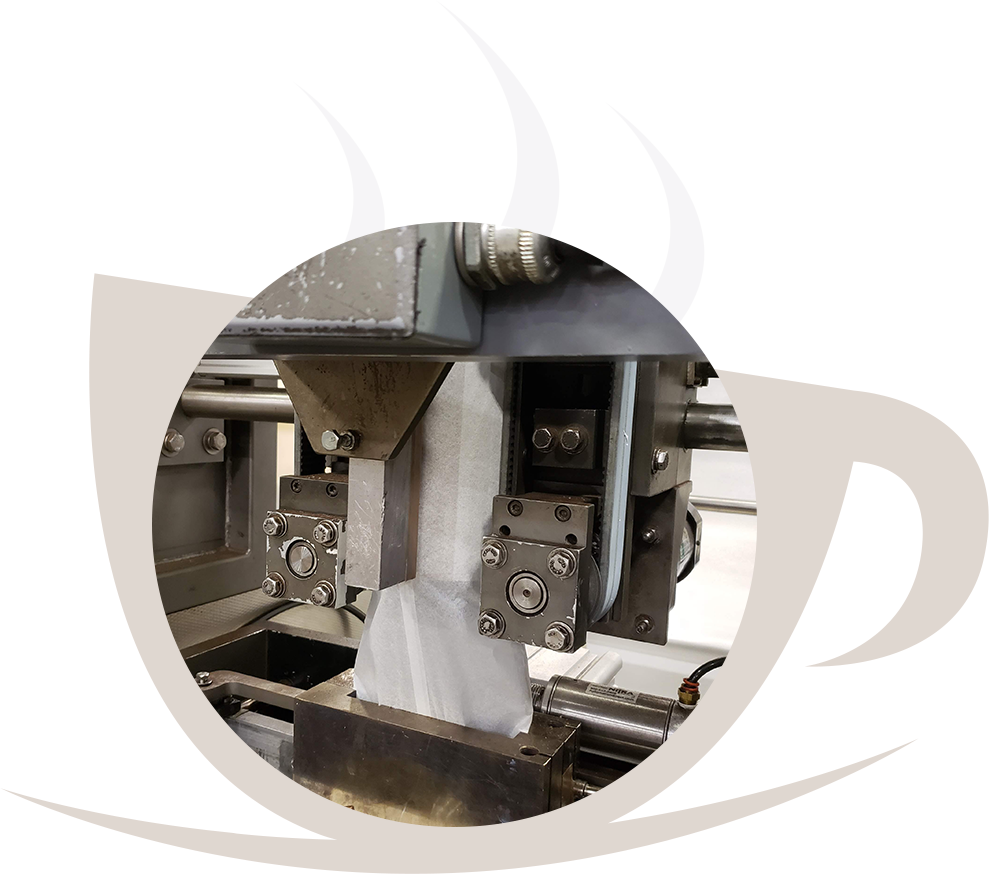

Grinding & Packaging

Roasted beans are either kept whole or ground using one of two industrial grinders set to the precise coarseness or fineness required. The coffee is then packaged, with options ranging from bulk to single-use portions, ensuring versatility for our clients.

Our packaging capabilities include custom logos, barcodes, and blend names. Each package is traceable through the lot number system, ensuring quality and freshness are preserved right up to the moment of enjoyment. Our packaging includes a one-way valve to seal in and maintain the coffee's peak freshness.

What Makes Our Process Special?

Intentional

Design

Our coffee roasting process is meticulously designed to ensure the utmost quality and consistency in every batch.

Crucial

Extra Step

Our approach includes a critical one-way degassing phase, where CO2 can escape from the beans without external gases entering. This crucial step enhances our coffee's stability, consistency, and overall flavor profile.

Testing &

Sorting

Every batch of green beans undergoes rigorous humidity testing upon arrival at our Roasterie, ensuring only the optimal beans make it into our roasts.

Industry

Leader

Our detail and commitment to quality has positioned us as the most efficient roasting operation in the Midwest, setting a new standard for excellence in coffee production.

A Whole New Level

of Customization

Developing a private-label coffee flavor enables you to enhance your brand identity and stand out in the market. Offering a unique blend helps build customer loyalty, maintain high-quality standards, and generate additional revenue.

This strategic initiative aligns with your company's values and improves the customer experience.